Sanitizer Machine

Welcome to the future of disinfection and hygiene brought to you by Robotshapers. Our revolutionary Automatic Disinfection Machine is designed to eliminate bacteria, viruses, and parasites, ensuring clean and safe surfaces in homes, offices, hospitals, schools, and public places. With cutting-edge features like UV-C light and disinfectants, our machine offers comprehensive cleaning methods to combat pathogens effectively.

Discover the versatility of our Disinfection Machine as it disinfects personal items, rooms, surfaces, equipment, and even public places. Equipped with advanced functions and operating modes, including time settings and autorun capabilities, our sterilizer provides customizable cleaning solutions tailored to your needs.

Join us as we delve into the world of disinfection technology and explore the countless applications of Robotshapers' Automatic Sanitizer Machine in various industries, ensuring a healthier and safer environment for all.

A Sanitizer machine, also known as a disinfection machine, is a device designed to disinfect or disinfect surfaces, equipment or areas to eliminate or reduce the presence of bacteria, viruses or parasites. These machines are frequently used in many places such as homes, offices, hospitals, schools and public places. Some important features of disinfectants are:

- Function: Disinfectants generally use several cleaning methods, for example:

- UV-C light: Some chemicals kill bacteria using ultraviolet (UV) light in the UV-C spectrum. bactericidal properties. and can kill or disable bacteria. UV-C light is effective against bacteria, viruses and molds.

- Disinfectants: Other disinfectants may use disinfectants such as hydrogen peroxide or alcohol solutions. These solutions are sprayed or applied to the surface, product or area to remove bacteria.

- Application: Disinfectors can disinfect many products and surfaces, including:

Personal items: They can disinfect small items such as mobile phones, keys, wallets, and other personal items that can cause contamination. . - Rooms and Surfaces: Disinfectants can be used to clean rooms, furniture, counters, doors, electrical switches, and other high-pressure areas.

- Equipment and tools: They can also be used for sterilization, tools and equipment used in clinics, laboratories or clinics.

- Public places: public places such as airports, train stations, shops and restaurants can use disinfectants to eliminate common contact and help control hygiene.

- Functions and Operating Modes: Sterilizers can have a variety of functions and operating modes, including:

- Time setting: Some machines allow you to set a cleaning schedule or cleaning cycle.

- Autorun: Some systems have motion or proximity sensors that activate the disinfection process when an object or person is detected.

Portable or Fixed: Sterilizers can be designed as portable or stationary devices according to their intended use. - Safety features: Some sterilizers have safety features such as shutting down when the machine is turned on or when it detects heat or low battery.

Required components :

1. Arduino Uno

2. Single Relay Channel

3. 12V, 5amp power supply

4. Infrared Sensor Switch E18 D80NKN Twins Chip

5. DGK Heavy Duty 12V DC Motor Pump 140 PSI

6. Spray Nozzles

DGK Heavy Duty 12V DC Motor Pump 140 PSI:

Garden Basket Farm Battery Sprayers The engine used in the battery sprayer may vary depending on the model and technical specifications of the production facility. However, some general details about the engines used in this type of sprayer are given below:

- Type: The motor used in farm battery sprayers with garden basket is generally electric. It can be a DC (direct current) motor or a non-DC (BLDC) motor.

- Power Rating: Engine power rating may vary depending on sprayer size and application. It is usually in the range of a few watts to tens of watts.

Voltage: The motor runs on a specific voltage supplied by the battery used in the sprayer. Most voltages for garden cart farm battery sprayers can be 12V or 24V, but other voltages are available. - Motor control: A motor can be controlled by a motor that controls the speed and direction of the motor. The motor controller can be integrated or separate from the control of the sprayer.

- Mixing pump: The motor is connected to the pump assembly, which is responsible for creating the pressure needed to spray the liquid. The motor drives the pump to create the necessary flow and pressure for spraying.

- Battery Power: The motor is powered by a rechargeable battery specially designed for the sprayer.Battery capacity and type vary depending on sprayer and time required.

- Safety features: Motors can have safety features such as overload protection or thermal protection to prevent damage from excessive current or temperature.

Fogg Nozzle:

Mist nozzles, also known as sprayers or spray nozzles, are devices designed to create fine water mist or water mist or other liquids. Here are some details about the bad nozzle:

- Operation: Mist nozzles combined with pressure and specially designed holes to atomize the liquid into tiny droplets. The liquid is forced to pass through the nozzle creating air or air.

- Nozzle Designs: Fog nozzles are available in various designs such as fixed orifice, adjustable orifice, and self-closing type. The nozzle design determines factors such as droplet size, spray pattern and flow rate.

- Droplet Size: The droplet size produced by mist nozzles can vary depending on the design and application. Fog nozzles can produce very fine droplets, usually 10 to 100 microns in diameter. Smaller droplets provide better shielding and evaporation, making them useful for certain applications.

- Spray patterns: Fog nozzles can have different spray patterns, including conical, fan, and even circular patterns. The spray pattern determines the coverage and distribution of air.

- Flow rate: The flow rate of the spray nozzle refers to the volume of liquid passing through the nozzle at one time. It is usually measured in gallons per minute (GPM) or liters per minute (LPM).Flow rate depends on specific nozzle design and desired application.

- Materials: Fog nozzles are usually made of materials such as brass, stainless steel or plastic. The selection of materials is based on properties such as durability, corrosion resistance and compatibility with spray fluids.

IR Sensor:

TheIR (Infrared) Magnetic Sensor is a sensor that detects the presence or proximity of objects by emitting and receiving infrared light.

Here are some details about the infrared proximity sensor:

- How it works: The infrared proximity sensor works by reflecting or reflecting infrared light. The sensor consists of an infrared emitter (usually an infrared LED) and an infrared receiver (such as a photodiode or phototransistor).

- Infrared Light Emission: The Infrared Emitter emits IR light in the form of a focused beam or a wide-angle spread, depending on the sensor design. The emitted light has a wavelength in the infrared spectrum that is invisible to the human eye.

- Reflection or Interruption Detection: When the emitted infrared light hits an object within the detection range, the light may be reflected back to the sensor or cut off, depending on whether the object goods are reflected or absorbed.

- Detection range: The detection range of the IR proximity sensor varies depending on the design and specifications of the sensor. It usually ranges from a few centimeters to several meters.

Single Channel Relay:

Single Channel Relay is an electronic switch that can control a single circuit or device. Here are some details about single channel relays:

- Operation: Single channel relays are usually controlled by an input signal such as voltage or current.

When the input signal meets the relay's activation criteria (for example, it reaches a voltage level), the relay switches its internal components to open or close the circuit. - Contacts: The contacts of single-channel relays can have two states: normally open (NO) or normally closed (NC).

When the relay is powered off, people are in their default state of being on or off. When the relay is energized, the contacts switch to the opposite state. - Load capacity: The load capacity of a relay refers to the maximum voltage and current it can withstand. It is important that you choose a relay with the appropriate capacity for the circuit or device you want to control.

- Coil Voltage: Single channel relays have a coil that requires a certain voltage to power the relay and open the contacts. Common coil voltages include 5V, 12V, 24V etc. is found. The coil voltage of the relay must match the voltage available in the control system.

- Switching Rate: The switching rate of a single-channel relay is the time it takes for the contacts to switch from one state to another after receiving an activation signal. Switching speed may vary depending on the relay model and feature.

- Mounting Options: Single channel relays are available as plug-in relays, panel mount relays or PCB mount relays. Mounting options depend on the purpose of the application, location and infrastructure.

- Application: A duct relay has many applications:

Home automation: control lights, fans or other electronic devices. - Automation: switching motors, pumps or solenoids.

- Automotive: Check car lights, actuators or circuits.

- HVAC Systems: Control of heating, ventilation and air conditioning equipment.

- Power Distribution: Manages equipment and power distribution in switches.

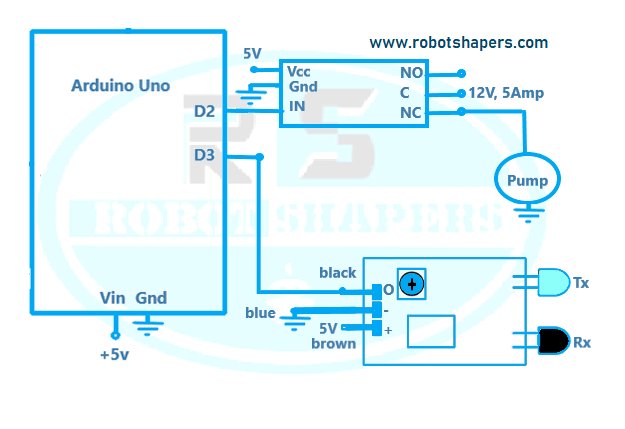

CIrcuit Diagram:

Code:

#define S 3// Sensor Pin

#define R 2// Relay Pin

void setup()

{

pinMode(S,INPUT);

pinMode(R,OUTPUT);

}

void loop() {

if (digitalRead(S)==LOW)

{

digitalWrite(R,HIGH);// switching on the pump

delay(6000);// delay for 6 second

}

if (digitalRead(S)==HIGH)

{

digitalWrite(R,LOW);// Keeping the pump off

}

}

Application:

- Sanitizer has many applications in various fields. It is used for disinfection and hygiene in homes, offices, schools, hospitals and public places.

- Disinfectants help remove germs and bacteria from personal belongings, surfaces and equipment.

- They are important for disinfecting homes, reducing contamination in healthcare facilities, cleaning food processing facilities and maintaining hygiene in public restrooms.

In addition, the sterilizer can be used in the industrial environment, agriculture, transportation and research facilities. - Their ability to attack objects and areas effectively helps create a safe and healthy environment for people and communities.

Best projects in Bhilai, Chhattisgarh, India. Contact: 7067150002

robotshapers1

robotshapers1